GEAR: WHAT IS UPE ARAMID?

- News

- Wing

Lightness, performance, and durability are the key words of the new fabric equipping our Team Series wings!

If UPE Aramid has emerged as an obvious choice for the Team Series wings, it is because of hundreds of tests conducted by our product team. Wings that we reserve for the most demanding wing foilers available on order. Starting with our team riders who have converted at the highest level all the potential that our development promised. With one victory and 3 places in the final four of the last Surf-Freestyle event of the season.

What competition results and performance in free sessions have confirmed to us about this new material:- Formidable dynamism in low wind conditions;

- More control when overpowered;

- An unprecedented feeling of lightness;

- Superior resistance to impacts;

- A significantly lower need for pressure;

- Rigidity that is never compromised.

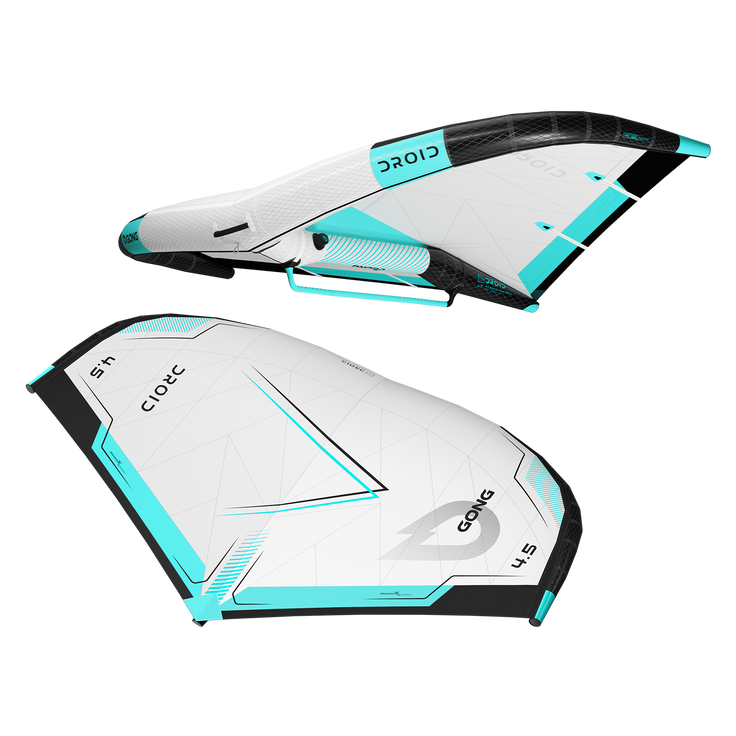

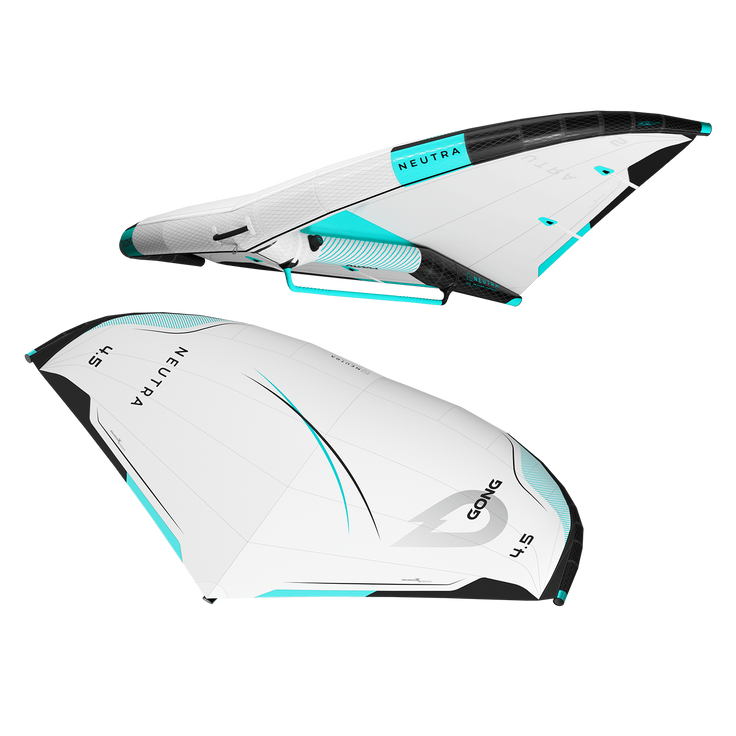

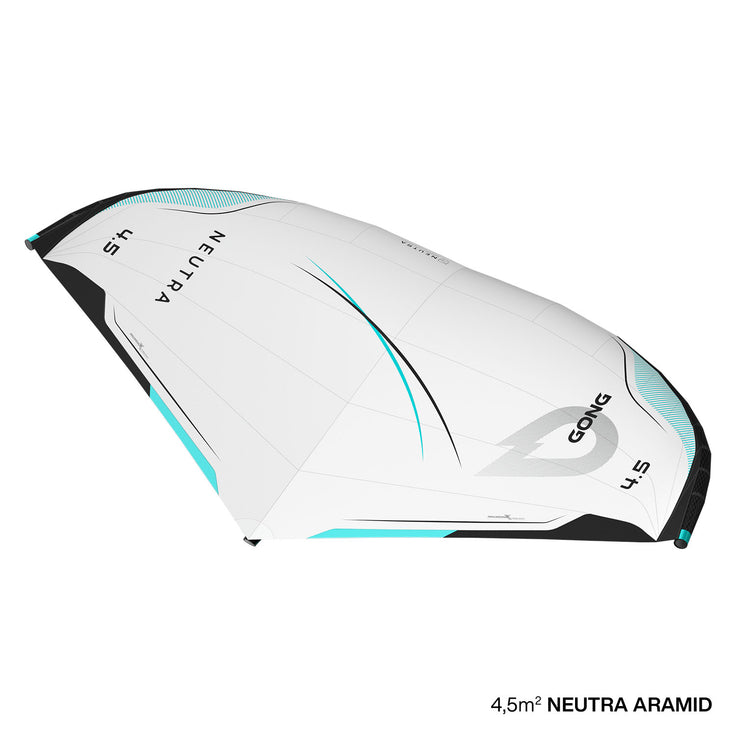

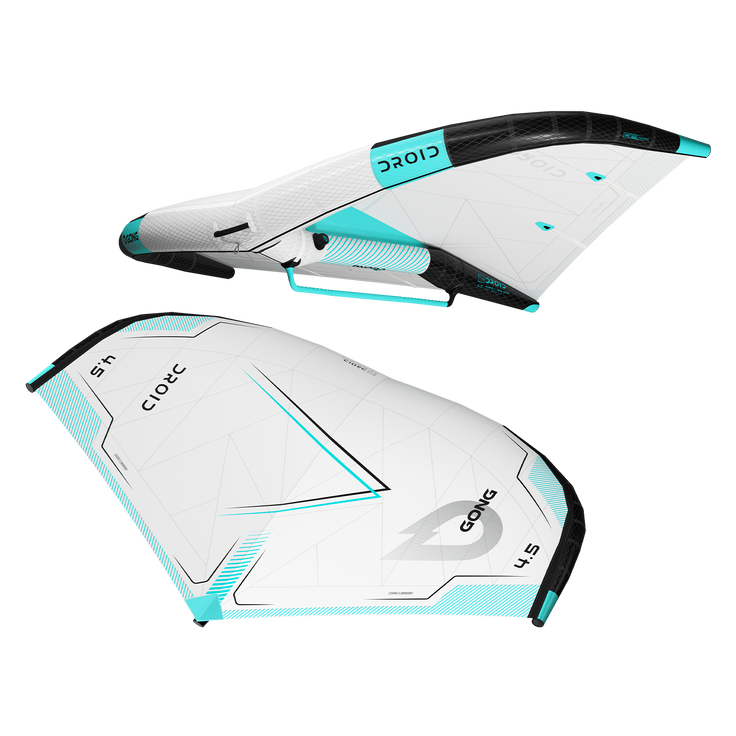

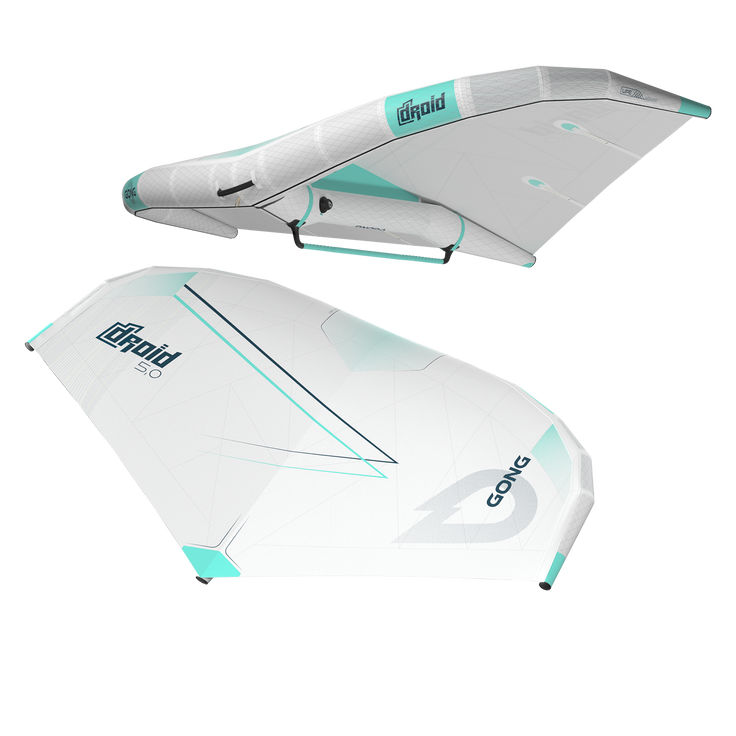

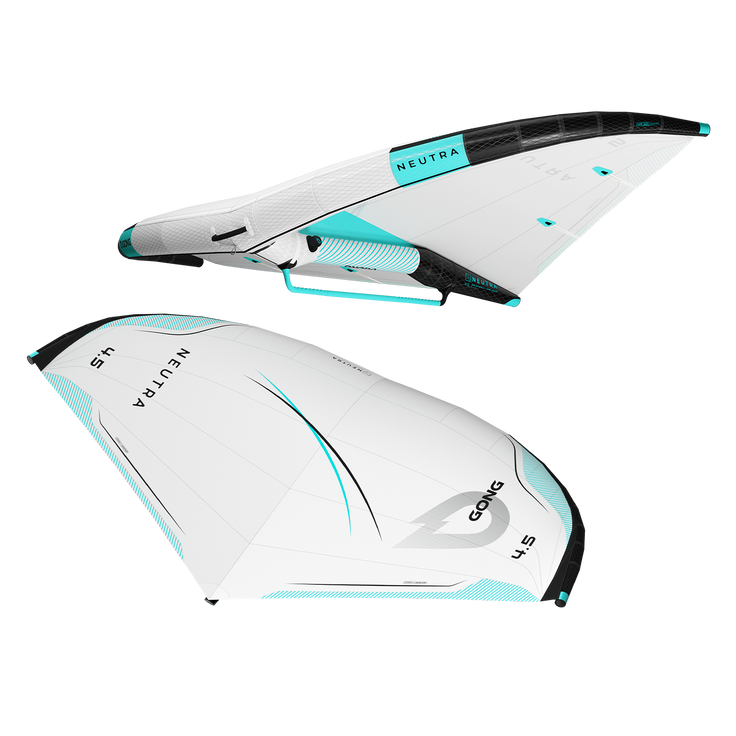

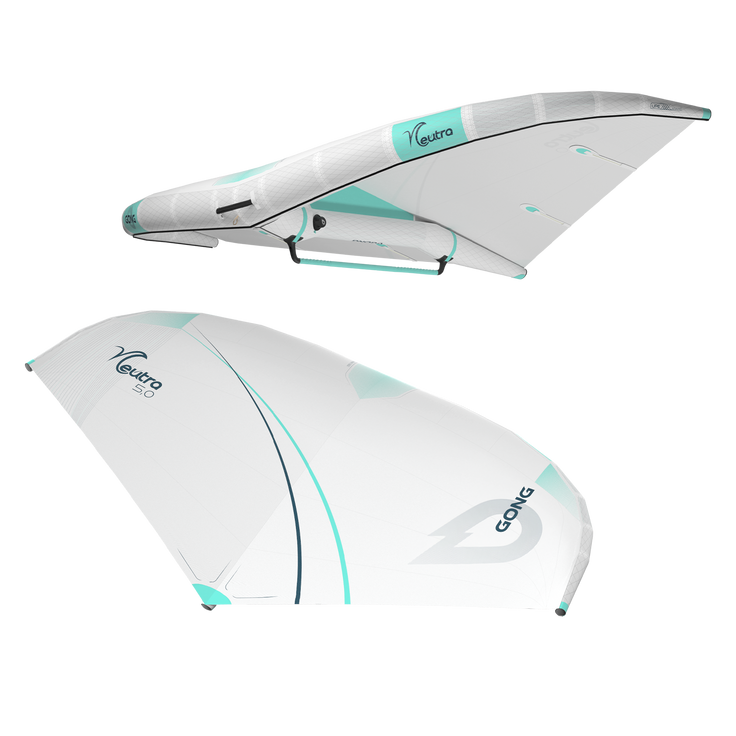

Qualities that Patrice Guénolé discusses in this Tech Talk on the Pulse DP in UPE Aramid, which, along with the Droid and the Neutra, are our wings that benefit from this technology.

Winger: Bastien, GONG team rider, with a Droid SP Aramid CZ.

Winger: Bastien, GONG team rider, with a Droid SP Aramid CZ.

Gains in lightness, rigidity and durability

UPE Aramid is the lightest and stiffest material on the market. At 85g/m2 (2 times less than Dacron!), this UPE Aramid present on the leading edge and the central batten ensures, in addition to a considerable weight savings (400g on a 5m2), an unparalleled gain in stiffness and reactivity. It’s simple: the wing no longer bends! We control its twisting through the Aramid axis and the design of the shape. Thus, deformations are no longer present.

In addition to its exceptional mechanical properties, this material also has a very low absorption rate. The wing gains very little weight when wet.

Obviously, a superb material without perfect assembly is worthless, and we have worked in infinite detail to ensure the reliability of the technical solutions for its implementation. For this, we have tested all known assemblies on traction machines and innovated with new and exclusive assembly methods at GONG to surpass the standards. Our wings have never been so robust.

Wingfoiler : Malo, GONG team rider, with a Droid Aramid X and Stunt FSP Pro.

Wingfoiler : Malo, GONG team rider, with a Droid Aramid X and Stunt FSP Pro.

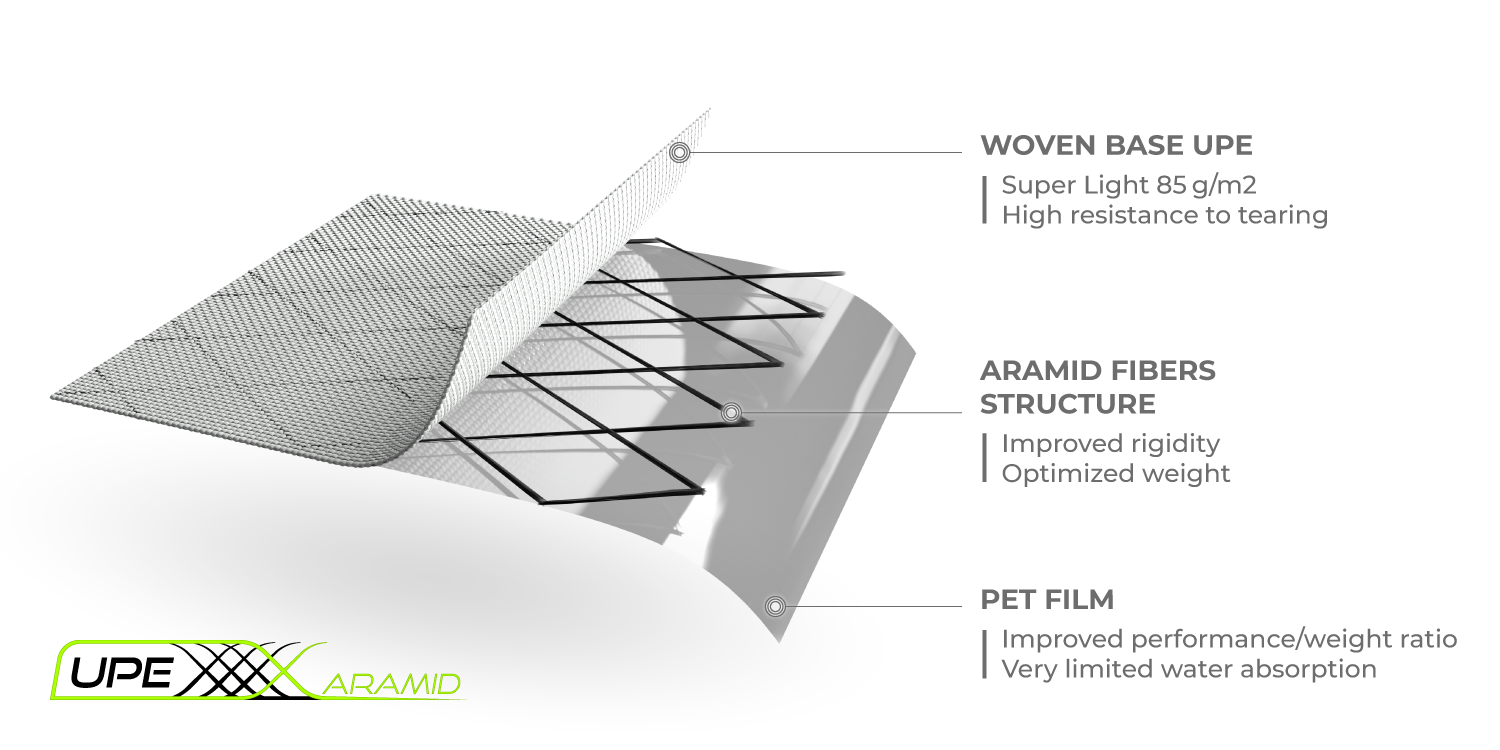

How does it work?

- The PET film ensures the connection between the elements and waterproofing.

- The Aramid fibers are arranged at a chosen angle to block the fabric’s extension under load without unnecessarily adding weight to the structure.

- The thin layer of UPE, lighter than on UPE 200, ensures strength. This tight weave of Dyneema fibers is a veritable shield.

These three laminated layers create a fabric that is both extremely lightweight, highly rigid, and very resistant to tearing.

Our exclusive assembly, tested in the laboratory and by the Pro Team, ensures unparalleled longevity for UPE Aramid.

The whole system is so rigid that 8 PSI gives you the rigidity of a UPE 200 at 15 PSI. It’s truly deformation-resistant.

Less pressure = less stress in the wing = less time spent pumping. More durability, performance, and lightness: the holy grail.

Wingfoiler : Malo, GONG team rider, with a Droid Aramid X and Stunt FSP Pro.

Wingfoiler : Malo, GONG team rider, with a Droid Aramid X and Stunt FSP Pro.